Dissemination of 3D advanced material processingto realize green society

Our research center promoted a four-years fundamental research program, from the 2018 to 2021 academic years, to realize a “Green Society” that embodies “Green Technology” that contributes to the preservation of the global environment, with the aim of developing society without damaging the future environment and everybody’s benefits of the future generations.

It was aimed to disseminate achievements of research in advanced material processing, (ABC + 3D), to realize green society. As a keyword for precise three-dimensional (3D) structure creation, research works were conducted for the purpose of establishing the fundamental technology and knowledge and promoting dramatic changes of industrial structures and energy, on three basic themes, A (Additive Manufacturing), B ( Biologically mediated (inspired) Control), C (Chemically mediated Control) ).

Additive Manufacturing

- 「Realization of smart machinery parts by multi-material 3D printing」

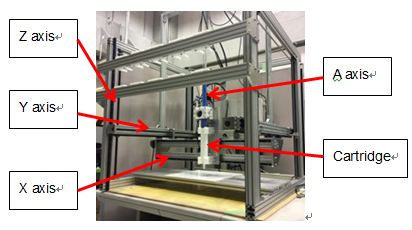

Due to the expiration of the basic patent for 3D printers, prototyping and development of 3D printers have been progressing around the world. The most common 3D printer based on the FDM method is based on the principle of supplying melted resin with heat from a nozzle, stacking layers and making model, which is so called additive manufacturing. In this study, the ME (Material Extrusion) method for cement-based materials was developed and the 3D printer was prototyped and optimized the modelling parameters.

- 「Realization of smart machinery parts by multi-material 3D printing」

Due to the expiration of the basic patent for 3D printers, prototyping and development of 3D printers have been progressing around the world. The most common 3D printer based on the FDM method is based on the principle of supplying melted resin with heat from a nozzle, stacking layers and making model, which is so called additive manufacturing. In this study, the ME (Material Extrusion) method for cement-based materials was developed and the 3D printer was prototyped and optimized the modelling parameters.

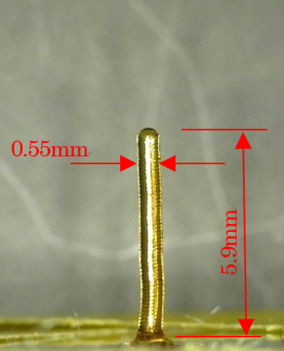

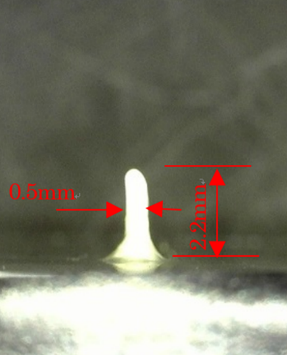

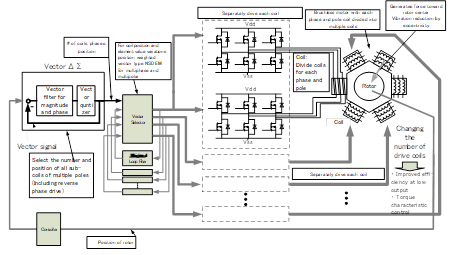

- 「Design of Slant Direct Drive Parallel Mechanism for 3D Printing System 」

Recently additive manufacturing has become a main stream manufacturing process. Different additive manufacturing processes build layers in different ways. Inkjet printing has a great potential for fast and accurate response to build layers. A prototype model of six degrees-of-freedom parallel mechanism stage for the fixed head type of 3D printing system was designed and fabricated. A pillar with high aspect ratio of 10.3 shown in Fig.1 was formed using the prototype model of the 3D printing system.

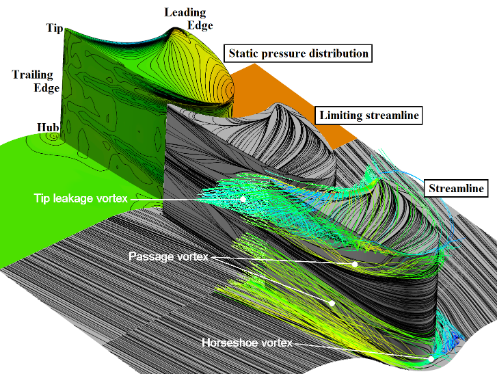

- 「Development of Novel Technology for Performance Improvement Turbomachinery by Application of 3D Printing」

An application of 3D printing technology to various areas of manufacturing is increasing rapidly, and also expanding in the manufacturing of turbomachinery which is seriously required to be improved in efficiency for the reduction of environmental load. Micro gas turbines for power generation usually adopt a single stage radial turbine impeller which possesses high expansion ratio per stage but is difficult to be equipped with any air cooling system because of the thin thickness of blade. As a consequence, it becomes difficult to enhance the efficiency of micro gas turbine by the increase of turbine inlet temperature. The increase of blade loading by the increase of blade turning angle in an axial turbine inevitably increases the relative blade thickness to the blade chord. Therefore, a highly loaded axial turbine blade may realize the improvement of the thermal efficiency of micro gas turbine by the application of cooling system. Then, the 3D printing technology makes it possible to manufacture the small size of axial turbine blade with a hollow structure, such as porous media, for air cooling.

In this study, in order to develop an axial turbine blade which can contribute to improve the efficiency of micro gas turbines, the experimental and the numerical investigations are conducted to clarify the complex flow structure and the associated loss generation mechanisms in an ultra-highly loaded turbine cascade (UHLC) with the turning angle of 160 degrees and the considerable thickness of blade. Figure 1 shows the static pressure distribution and the limiting streamlines on the solid walls and the three-dimensional streamlines exhibiting the complex vortex structure in the UHLTC obtained by the CFD (Computational Fluid Dynamics).

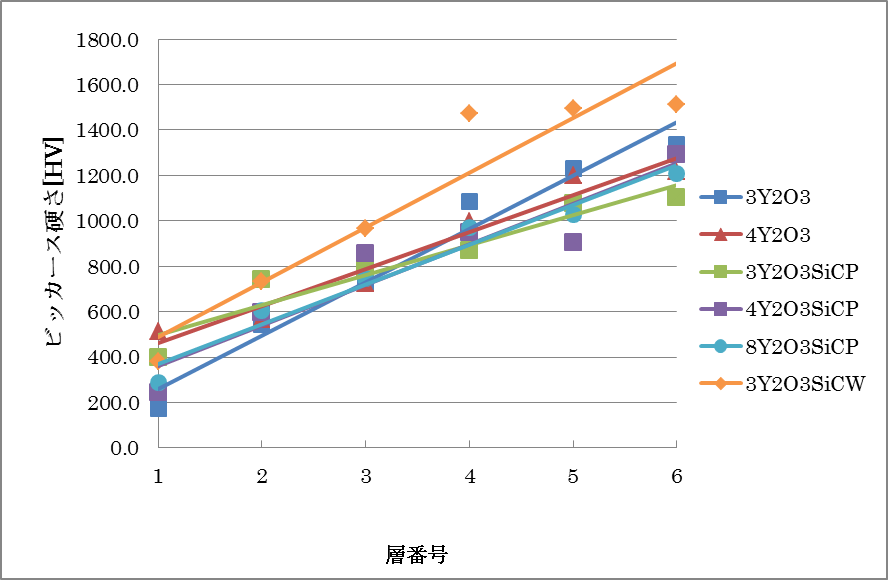

- 「Additive manufacturing for multifunctional ceramics-based functionally graded materials with 3D complex structures」

Additive manufacturing has been hardly applied to 3D printer for ceramics because of their high meting points, which prevents local melting of the materials, that is the process used in 3D printer for plastics and metals. In this research, microwave-enhanced sintering with self-heating effects related to dependence of dielectric losses on temperatures, and spark plasma sintering with direct pulsed current can be applied to additive manufacturing for ceramics. Based on these consolidation techniques, fabrication processes for multifunctional ceramics-based functionally graded structures are to be studied and established.

Biologically mediated (inspired)Control

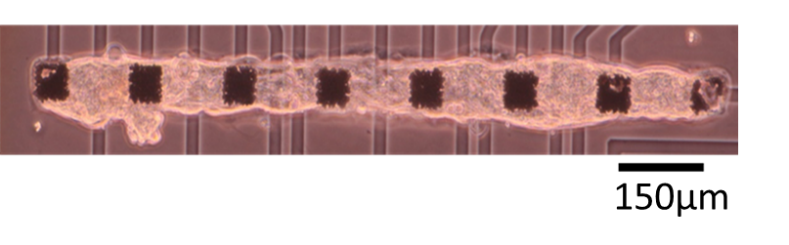

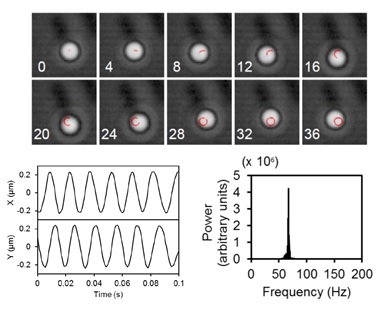

- 「Reconstruction of 3D heart structure by using cardiomyocyte networks」

Heart is an important organ having a function to pump blood to other organs. In advanced medical care such as cardiomyocyte sheets, it is difficult to show the equal function of heart owing to random cell arrangement. Therefore, using an agarose microchamber and 1 cell arrangement technology, we will reconstruct the 3D heart having the equal function of real heart. Then they would contribute to the development of the reconstructive technology in regenerative medicine by reconstruction of a functional heart tissue.

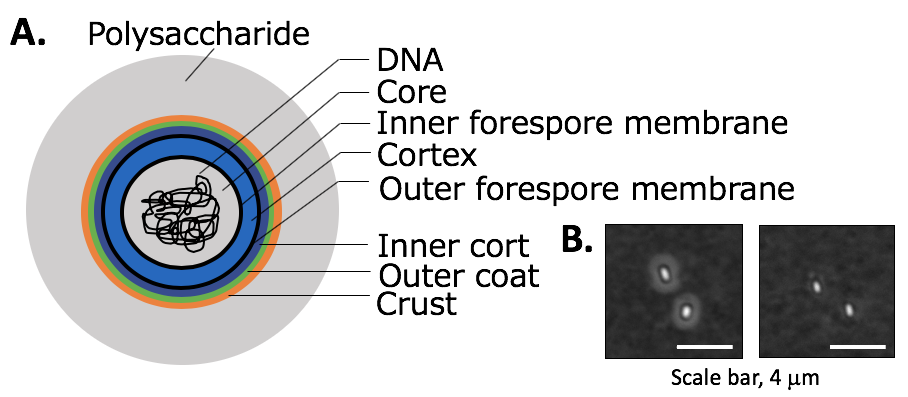

- 「Analysis of bacterial spore layers and its application 」

Bacterial spores have multiple layers, protein coats and polysaccharide, which allow highly resistant to heat, drying, and chemicals. Although some spore-forming bacteria such Bacillus subtilis (natto) are used specifically in the fermentation of natto, many spore formers are special problems for other food industry because of such resistances. The goal of this research is to explore mechanisms of spore layer formation and to control spores by altering the spore-surface structure.

- 「Analysis of bacterial spore layers and its application 」

Bacterial spores have multiple layers, protein coats and polysaccharide, which allow highly resistant to heat, drying, and chemicals. Although some spore-forming bacteria such Bacillus subtilis (natto) are used specifically in the fermentation of natto, many spore formers are special problems for other food industry because of such resistances. The goal of this research is to explore mechanisms of spore layer formation and to control spores by altering the spore-surface structure.

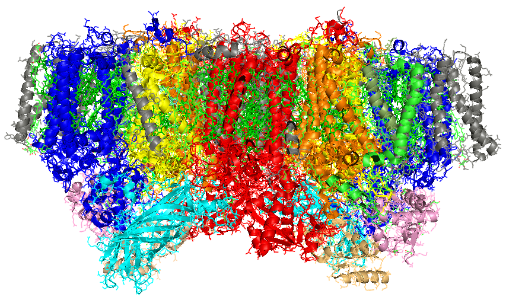

- 「Study on stabilization of photosynthetic machineries」

In order to industrially utilize natural photosynthetic machineries, it is necessary to isolate the photosynthetic machineries from photosynthetic organisms and store them in an active state. Photosystem II is a photosynthetic machinery, which oxidizes and decomposes water using light energy to generate oxygen. The purpose of this study is to develop technology that isolate intact photosystem II preparations from cyanobacteria retaining the high photosynthetic activities that will remain stable for a long time.

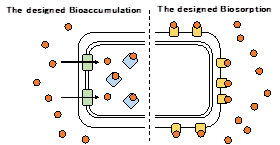

- 「Development of functional materials with bioprocess using the designed Escherichia coli bacteria」

Metal is useful industrial material. To establish sustainable consumption and production circulation, the bioprocess is known to be available in the stable supply of metal materials isolated not only from wastes but also from water sea. This aim is to design and construct the recombinant Escherichia coli for biosorption and bioaccumulation of useful metal.

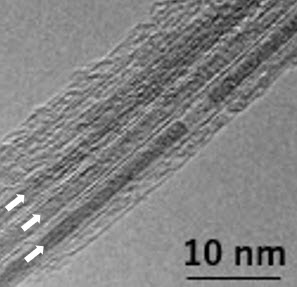

- 「Development of a wastewater treatment method by using a novel soil infiltration system with nano-structure controlled inorganic ion exchangers」

Layered clay minerals and zeolites have the adsorption ability for various harmful substances using their layers and pores. A wastewater purification system (a soil infiltration system) has been used by applying these characteristics. But these materials may form fine particles in an aqueous solution and cause clogging of the filter. The purpose of this study is to develop a novel soil infiltration system, with nano-structure controlled inorganic ion exchangers or combining them with other materials.

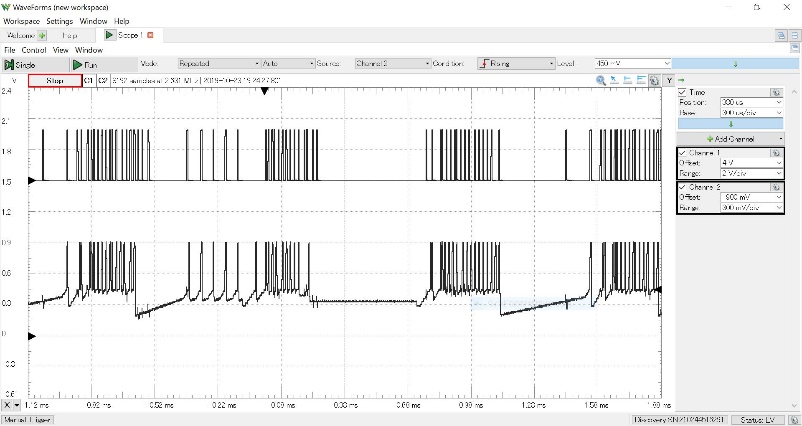

- 「High Performance Biomorphic System Design – Cochlear Implant and Neural Prosthetic Device」

In this study, large scale integrated circuits that can reproduce excellent functions of biological systems are designed. For example, a design method of a large scale integrated circuit to reproduce the nonlinear dynamics of mammalian cochlea is developed and its application to cochlear implant is studied. Also, a design method of a large scale integrated circuit to reproduce the complex dynamics of the brain is developed and its application to neural prosthetic device is studied.

Chemically mediated Control

- 「Development of Surface Reforming Process of Alloy by Mounting of Laminated Ceramic Particles」

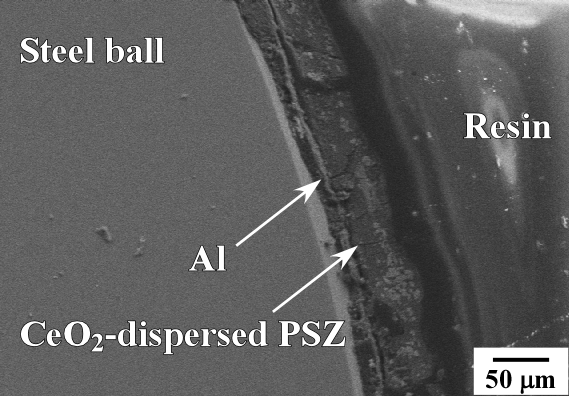

For application of ball bearings, surface reforming processes have been developing to improve the sliding characteristics and wear resistance of bearing steel ball by using a mounting technique of laminated ceramic particles. In the present study, coefficient of friction between the bearing steel ball and iron plate can be decreased by coating of aluminum bonding layer and precursor solution of partially-stabilized zirconia layer dispersed with nano-particles, and successive heat treatments under controlled atmospheres.

- 「Development of Surface Reforming Process of Alloy by Mounting of Laminated Ceramic Particles」

For application of ball bearings, surface reforming processes have been developing to improve the sliding characteristics and wear resistance of bearing steel ball by using a mounting technique of laminated ceramic particles. In the present study, coefficient of friction between the bearing steel ball and iron plate can be decreased by coating of aluminum bonding layer and precursor solution of partially-stabilized zirconia layer dispersed with nano-particles, and successive heat treatments under controlled atmospheres.

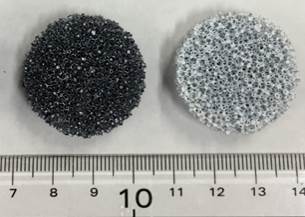

- 「Synthesis of 3D structure-controlled oxide and hydroxide particles and their application to energy and environmental materials 」

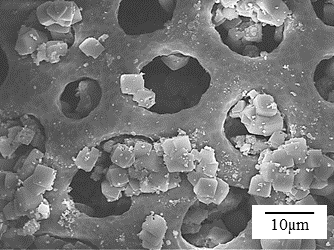

3D structure-controlled oxide and hydroxide particles are fabricated via highly controlled bottom-up process of precursors in solution to produce crystalline porous bodies, aiming at application to energy-related materials and environmental materials. Macroporous bodies with both penetrating pores and large porosity are fabricated for the application of water purification filter materials. Crystalline mesoporous materials with nano-order mesopores are prepared through the prescely controlled bottom-up of nanoclusters and applied to obtain higher performance electrochemical devices.

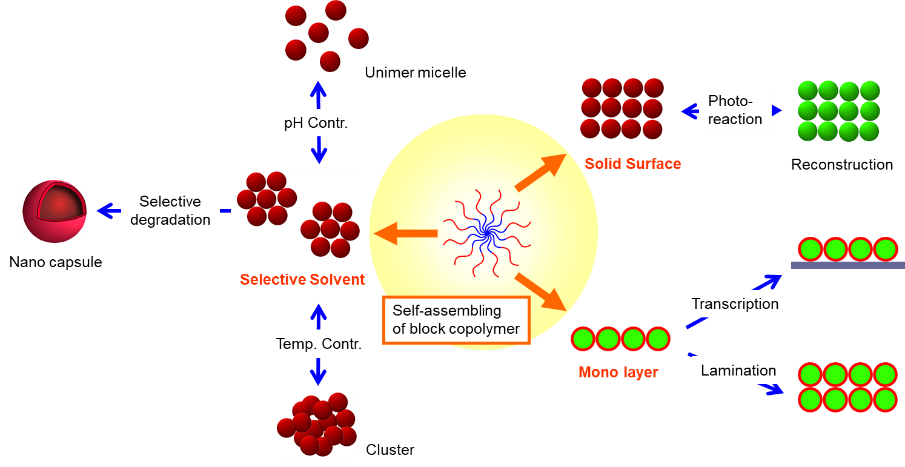

- 「Development of Photoreactive Soft Materials」

Synthesis and application of the amphiphilic block copolymers functionalized with photoreactive groups will be investigated in order to develop the novel functional soft materials taking advantage of their self-assembly behavior in the selective solvent. For instance, the functional nano-capsule will be formed by the selective decomposition of the unreacted domain. The potentially application of these nano-capsules for the development of next-generation electronic materials will be also expected to construct a perfect phase structures in which conductors and insulators are 3D-stacked at the nano level.

- 「Development of Photoreactive Soft Materials」

Synthesis and application of the amphiphilic block copolymers functionalized with photoreactive groups will be investigated in order to develop the novel functional soft materials taking advantage of their self-assembly behavior in the selective solvent. For instance, the functional nano-capsule will be formed by the selective decomposition of the unreacted domain. The potentially application of these nano-capsules for the development of next-generation electronic materials will be also expected to construct a perfect phase structures in which conductors and insulators are 3D-stacked at the nano level.

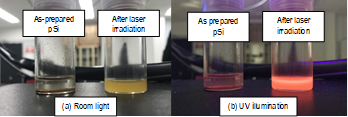

- 「Efficient laser irradiation process for Si quantum dots in liquid」

Crystalline silicon nanoparticle (Si quantum dot) is a promising material for future light-emitting devices and biomedical applications because of its environmental friendliness and low cost. Laser irradiation in liquid is a simple top-down method for the formation of the Si quantum dot. To realize a practical laser irradiation process for the Si quantum dot, we have developed an efficient formation process for Si quantum dot via laser irradiation of the porous Si in liquid.